Kies hier je land en taal

- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

Welkom bij Mitutoyo Nederland, België en Danmark

Welkom bij Mitutoyo Nederland, België en Danmark

Welkom bij Mitutoyo Nederland, België en Danmark

Welkom bij Mitutoyo Nederland, België en Danmark

- Alle Product Highlights

- Nieuw SmartMeasure-AL

- Nieuwe SJ-220

- Nieuwe QuantuMike

- LEGEX Takumi

- Schuifmaten

- Measurlink 10

- HR-600 Series

- TAGLENS

- MCOSMOS 5

- Crysta Apex V

- Formtracer Avant

- MiSTAR 555

- Bluetooth Data Communicatie

- Profielprojector PJ Plus

- QuickVision Pro

- Alle Producten per Industrie

- MeasurLink 10

- MeasurLink 10

- Medical

- Automotive

- Aerospace

- Energy

- Gen. Manufacturing

- Electronics

- Case Studies

- Alle Handmeetgereedschappen

- Schuifmaten

- Schroefmaten

- Binnenmeetinstrumenten

- Diepte meetinstrumenten

- Hoogtemeters

- Meetklokken en Snelopnemers

- Hulpstukken en diversen

- Kalibratie instrumenten

- Eindmaten

- Geautomatiseerde meetsystemen

- Alle CMM

- Kleine en middelgrote CMM's

- In-Line en werkvloer CMMs

- CMMs met grote afmetingen

- CMM Rotatie tafels

- CMM Tastsystemen

- Styli

- Opspansystemen

- CMM Accessoires

- CMM Software

- SmartMeasure-AL

- Alle Vision

- 2D Vision Meetsystemen Quick Image

- Manueel 3D Vision Meetsystemen Quick Scope

- 3D CNC Vision Meetsystemen Quick Vision

- 3D CNC Multisensor Meetsystemen Quick Vision

- 3D CNC Meetsystemen voor Micro Geometrieën

- Objectieven en kalibratiekaarten

- Alle Optisch

- Loepen

- Profiel Projectoren

- Meetmicroscopen

- Microscoop Units

- Oculairs en Objectieven

- TAGLENS

- Schuifmaten

- Digitale schuifmaten

- Schuifmaten voor speciale doeleinden

- Analoge schuifmaten

- Schuifmaat accessoires

- Schroefmaten

- Digimatic schroefmaten & Analoge schroefmaten

- Accessoires voor schroefmaten

- Inbouwschroefmaten

- Accessoires voor inbouwschroefmaten

- Binnenmeetinstrumenten

- Binnenmeetinstrumenten

- Binnenmeettasters

- Accessoires voor binnenmeetinstrumenten

- Meetklokken en Snelopnemers

- Digitale meetklok

- Accessoires voor meetklokken

- Zwenktaster

- Meetklok

- Accessoires voor meetklokken

- Diktemeter, dieptemeter

- Hulpstukken en diversen

- Statieven

- Precisie spanklemmen

- Vlakplaten en sinusplaten

- Hoekmetingen en raamwaterpassen

- Voelermaten en linialen

- Eindmaten

- Stalen eindmatensets

- Stalen losse eindmaten

- CERA eindmatensets

- CERA keramische losse eindmaten

- Speciale eindmaten

- Accessoires voor eindmaten

- Kleine en middelgrote CMM's

- CRYSTA-Apex V - 500, 700, & 900 Series

- CRYSTA-Apex V - 1200 Series

- CRYSTA-Apex V - 1600 & 2000 Series

- CRYSTA-Apex EX Series for REVO

- STRATO-Apex - 500, 700, & 900 Series

- STRATO-Apex - 1600 Series

- LEGEX Series

- Styli

- Styli Kits

- Rechte tasters

- Diamant Tasters

- IJkkogel Keramiek Ø10,0 mm

- Tasters voor bewerkingsmachines

- Ster Tasters

- Tasters voor Ster Tasters

- Cilinder Tasters

- Schijf Tasters

- Tip Tasters

- Verlengstukken

- Houders

- Adapters

- Verbindingstukken

- Bevestiging voor taster onderdelen

- Gereedschappen voor Tasters

- StyliCleaner

- Opspansystemen

- CMM-opspansets

- eco-fix pallet opspansysteem kits

- FixtureBuilder Software

- eco-fix schroeven en gereedschappen

- eco-fix en eco-fix uitbreidingssets

- eco-fix en eco-fixplus-componenten

- 3D CNC Vision Meetsystemen Quick Vision

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

- Profiel Projectoren

- Profiel Projector PJ Serie

- Profiel Projector PV Serie

- Profiel Projector PH Serie

- Data Processor QM-Data

- Accessories

- Meetmicroscopen

- TM Series Gen. B

- MF Series Gen. D

- MF-U Series Gen. D

- Illumination Sources

- Vision Unit

- M2 Software

- QSPAK-VUE Software

- Oculairs en Objectieven

- ML-Series Objectives

- Brightfield Observation Objectives

- Brightfield/Darkfield Observation Objectives

- NIR Objectives

- NIR LCD Objectives

- NUV Objectives

- NUV LCD Objectives

- UV Objectives

- UV LCD Objectives

- Oppervlakte ruwheid

- Surftest SJ-220

- Surftest SJ-310

- Surftest SJ-410

- Surftest SJ-500

- Surftest SV-2100

- Surftest SJ-500P

- Surftest SV-2100P

- Formtracer Avant FTA-S3000

- Surftest Extreme SV-3000CNC

- Surftest Extreme SV-M3000CNC

- Oppervlakte ruwheid & Contour

- Formtracer Avant FTA-D3000 / FTA-D4000 Series

- Formtracer CS-3300

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Type 1

- Formtracer Extreme CS-5000CNC and CS-H5000CNC

- Portable Hardness Testers

- Impact Type Hardheid Test Unit HARDMATIC HH-V400

- Digital and Analogue Durometers HARDMATIC HH-300

- Reference materials and indenters

- Hardness reference materials

- Hardness indenters and replacement balls

- Meettasters

- ABSOLUTE Digimatic Linear Gauge LGS Series

- Air Drive Unit

- ABSOLUTE Digimatic Linear Gauge LGD Series

- Standard Linear Gauge LGF Series

- Linear Gauge LG100 Series

- Linear Gauge LG200 Series

- Slim Head Linear Gauge LGK Series

- Slim Head Linear Gauge LGB Series

- Large Measuring Range Linear Gauge LG

- Laser Hologauge

- Lage meetkracht meetinstrument

- LITEMATIC VL-50 Gemotoriseerde lage meetkracht, zeer hoog nauwkeurig meetinstrument

- Tellers en uitleeseenheden

- EJ Counter and Interfaces for Linear Gauges

- EC Counter for Linear Gauges

- EG Counter for Linear Gauges

- EH Counter for Linear Gauges

- EV Counter for Linear Gauges

- Display Unit for EV Counter

- Laser Scan Micrometers

- Laser Scan Micrometer Measuring Unit

- Laser Scan Micrometer Controller Unit

- Laser Scan Micrometer Interface Unit

- Laser Scan Micrometer Optional Accessories

- DRO Linear Scales en Tellers

- DRO Linear Scales AT103

- DRO Linear Scales AT103 - High Accuracy

- DRO Linear Scales AT113

- DRO Linear Scales AT113 - High Accuracy

- DRO Linear Scales AT116

- DRO ABS Linear Scales AT715

- Universal DRO KA-200 Counter

- NC Linear Scales

- NC Linear Scales ST36

- NC Linear Scales ST46-EZA

- NC Linear Scales ABS ST700

- NC Linear Scales ABS ST1300

- NC Linear Scales AT211

- NC Linear Scales ABS AT1100

- NC Linear Scales ABS AT1300

- NC Linear Scales AT402E

- NC Linear Scales AT203

- NC Linear Scales AT402E with cable A/B

- NC Linear Scales AT402E with cable C

- Opbouwlinialen

- Horizontal ABSOLUTE Scale Coolant Proof IP66

- Horizontal ABSOLUTE Scale Standard

- Horizontal ABSOLUTE Scale Measurement Direction Switching

- Horizontal ABSOLUTE Scale Diameter Function

- Vertical ABSOLUTE Scale Standard

- Vertical ABSOLUTE Scale Measurement Direction Switching

- Vertical ABSOLUTE Scale Diameter Function

- Signaal kabels

- USB Input Tool Direct Kabel

- Digimatic Data Kabels

- Verlengkabels voor Digimatic Kabels

- Draadloze communicatie

- Wireless Communication System U-WAVE

- U-WAVE Bluetooth

- U-WAVE-T Connection Cables and Connection Units

Original Equipment Manufacturers (OEM)

Original Equipment Manufacturers (OEM)

Mitutoyo OEM can address missing expertise or resources by supplying you with our renowned Metrology equipment that seamlessly integrates into your products.

Aerospace

Aerospace

Complex aerospace applications need fast, extremely precise quality control to ensure accurate assemblies. See how Mitutoyo makes it happen.

Automotive

Automotive

The automotive industry continues to innovate, and Mitutoyo delivers the advanced inspection and scanning capabilities to help manufacturers achieve ongoing production

Energy

Energy

Make critical equipment components for oil and gas, solar, wind, or nuclear as precise as possible with advanced metrology solutions from Mitutoyo.

Medical

Medical

Boast unmatched accuracy and reliability for diagnostic and therapeutic devices, pharmaceutical goods, and countless other highly sensitive medical engineering applications with leading precision metrology solutions.

Gen. Manufacturing

Gen. Manufacturing

Ensure high repeatability and rigorous quality control with form measurement solutions, coordinate measuring machines and precision measuring tools from Mitutoyo.

Electronics

Electronics

The non-contact and vision measurement solutions from Mitutoyo bring microscopic accuracy to smaller and denser electronic components.

Case Studies

Case Studies

For an overview of Mitutoyo's capabilities, this is no greater place to look than our marvelous collection of case studies.

Mitutoyo Integrators

Mitutoyo Integrators

Integrating your measuring devices into existing processes made easy

Product Demos

Product Demos

Online of offline, get a product demonstration today

Manufacturing Automation Integration

Manufacturing Automation Integration

Turn your factory into a smart factory with the help of Mitutoyo

Custom Products

Custom Products

Custom-made products for unique applications

Connectivity

Connectivity

Mitutoyo offers a range of products that incorporate connectivity features to enhance data management, analysis, and productivity.

Helpdesk Support

Helpdesk Support

Gratis Helpdesk support voor klanten met service contracten

Kalibratie Services

Kalibratie Services

Laat je meetapparatuur kalibreren door een laboratorium dat je vertrouwt

Meetservices

Meetservices

Laat uw werkstukken en onderdelen opmeten door onze Aukom gecertificeerde specialisten

Reparaties & Reserve onderdelen

Reparaties & Reserve onderdelen

Reserveonderdelen en reparaties voor Mitutoyo-apparaten

Service contracten

Service contracten

Klantgericht servicecontractconcept in onderhoud en kalibratie

Education Pack

Education Pack

Er is geen betere hulp dan posters of lesmateriaal van Mitutoyo, perfect voor de werkplaats of het klaslokaal.

E-Learning

E-Learning

Voor degenen die geïnteresseerd zijn in metrologie biedt Mitutoyo E-Learning-cursussen om studenten, personeel of zelfs hobbyisten op te leiden.

Online Material

Online Material

Als je op zoek bent naar een snelle manier om meer te leren over meten, bekijk dan onze vele instructievideo's

Ontdek Mitutoyo

Ontdek Mitutoyo

Het grootste metrologiebedrijf ter wereld

Certificeringen en legitimiteit

Certificeringen en legitimiteit

Bekijk hier onze certificeringen, accreditaties en legitimiteit zodat u verzekerd bent van betrouwbare en geverifieerde diensten.

Merchandise

Merchandise

Voor degenen die in stijl over de winkelvloer willen lopen, ga naar de shop en steun je favoriete merk.

Pers informatie

Pers informatie

Bekijk onze laatste persberichten.

Alle nieuwsberichten

Alle nieuwsberichten

Lees hier meer nieuws over Mitutoyo Nederland, België en Denemarken. Deze pagina wordt regelmatig vernieuwd.

Product informatie

Product informatie

Bekijk en download onze catalogus, productbrochures en meer

Software

Software

Download onze software en updates gemakkelijk en snel

Verklaringen van conformiteit

Verklaringen van conformiteit

Hier kun je de volledige versies voor de EU en het VK downloaden

Gratis wallpapers

Gratis wallpapers

Download hier gratis de officiële wallpapers van Mitutoyo

Online Catalogus

Online Catalogus

Bekijk ons uitgebreide assortiment in onze online catalogus!

-

Products

- Terug Products

- Products

- Product Highlights

-

Producten per Industrie

- Terug Producten per Industrie Alle Producten per Industrie

- MeasurLink 10

- MeasurLink 10

- Medical

- Automotive

- Aerospace

- Energy

- Gen. Manufacturing

- Electronics

- Case Studies

-

Handmeetgereedschappen

- Terug Handmeetgereedschappen Alle Handmeetgereedschappen

- Schuifmaten

- Schroefmaten

-

Binnenmeetinstrumenten

- Terug Binnenmeetinstrumenten Binnenmeetinstrumenten

- Binnenmeetinstrumenten

- Binnenmeettasters

- Accessoires voor binnenmeetinstrumenten

-

Diepte meetinstrumenten

- Terug Diepte meetinstrumenten Diepte meetinstrumenten

- Diepte schroefmaat

- Diepteschuitmaat

- Diepteschuifmaat accessoires

- Hoogtemeters

- Meetklokken en Snelopnemers

- Hulpstukken en diversen

-

Kalibratie instrumenten

- Terug Kalibratie instrumenten Kalibratie instrumenten

- Hoogteschroefmaat Height Master

- Stappeneindmaat

- Kalibratie apparatuur

- Eindmaten

- Geautomatiseerde meetsystemen

-

CMM

- Terug CMM Alle CMM

- Kleine en middelgrote CMM's

-

In-Line en werkvloer CMMs

- Terug In-Line en werkvloer CMMs In-Line en werkvloer CMMs

- MACH Ko-ga-me

- MACH 3A 653

- MACH V 9106

- MiSTAR 555

-

CMMs met grote afmetingen

- Terug CMMs met grote afmetingen CMMs met grote afmetingen

- CARB-Series

- CMM Rotatie tafels

-

CMM Tastsystemen

- Terug CMM Tastsystemen CMM Tastsystemen

- SurfaceMeasure

- REVO

- SP80

- TP7M

-

Styli

- Terug Styli Styli

- Styli Kits

- Rechte tasters

- Diamant Tasters

- IJkkogel Keramiek Ø10,0 mm

- Tasters voor bewerkingsmachines

- Ster Tasters

- Tasters voor Ster Tasters

- Cilinder Tasters

- Schijf Tasters

- Tip Tasters

- Verlengstukken

- Houders

- Adapters

- Verbindingstukken

- Bevestiging voor taster onderdelen

- Gereedschappen voor Tasters

- StyliCleaner

- Opspansystemen

-

CMM Accessoires

- Terug CMM Accessoires CMM Accessoires

- Behuizingen

- Veiligheidssystemen

-

CMM Software

- Terug CMM Software CMM Software

- MiCAT Planner

- MCOSMOS

- MAFIS Express

- MSURF

- SmartMeasure-AL

-

Vision

- Terug Vision Alle Vision

-

2D Vision Meetsystemen Quick Image

- Terug 2D Vision Meetsystemen Quick Image 2D Vision Meetsystemen Quick Image

- Quick Image

- Quick Image Software

-

Manueel 3D Vision Meetsystemen Quick Scope

- Terug Manueel 3D Vision Meetsystemen Quick Scope Manueel 3D Vision Meetsystemen Quick Scope

- Manual Quick Scope

- Quick Scope Software

-

3D CNC Vision Meetsystemen Quick Vision

- Terug 3D CNC Vision Meetsystemen Quick Vision 3D CNC Vision Meetsystemen Quick Vision

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

-

3D CNC Multisensor Meetsystemen Quick Vision

- Terug 3D CNC Multisensor Meetsystemen Quick Vision 3D CNC Multisensor Meetsystemen Quick Vision

- Quick Vision Hybrid

- Quick Vision WLI

-

3D CNC Meetsystemen voor Micro Geometrieën

- Terug 3D CNC Meetsystemen voor Micro Geometrieën 3D CNC Meetsystemen voor Micro Geometrieën

- UMAP Vision Systems

- UMAP Software

- Objectieven en kalibratiekaarten

- Optisch

- Vorm

-

Hardheid

- Terug Hardheid Alle Hardheid

- Portable Hardness Testers

-

Hardness Testing Software

- Terug Hardness Testing Software Hardness Testing Software

- AVPAK

-

Reference materials and indenters

- Terug Reference materials and indenters Reference materials and indenters

- Hardness reference materials

- Hardness indenters and replacement balls

-

Sensoren

- Terug Sensoren Alle Sensoren

-

Meettasters

- Terug Meettasters Meettasters

- ABSOLUTE Digimatic Linear Gauge LGS Series

- Air Drive Unit

- ABSOLUTE Digimatic Linear Gauge LGD Series

- Standard Linear Gauge LGF Series

- Linear Gauge LG100 Series

- Linear Gauge LG200 Series

- Slim Head Linear Gauge LGK Series

- Slim Head Linear Gauge LGB Series

- Large Measuring Range Linear Gauge LG

- Laser Hologauge

-

Lage meetkracht meetinstrument

- Terug Lage meetkracht meetinstrument Lage meetkracht meetinstrument

- LITEMATIC VL-50 Gemotoriseerde lage meetkracht, zeer hoog nauwkeurig meetinstrument

- Tellers en uitleeseenheden

- Laser Scan Micrometers

-

Surface Measure

- Terug Surface Measure Surface Measure

- Surface Measure 1008S

- Accessories

- Sensor Management Software

-

Digital Scales

- Terug Digital Scales Alle Digital Scales

- DRO Linear Scales en Tellers

-

NC Linear Scales

- Terug NC Linear Scales NC Linear Scales

- NC Linear Scales ST36

- NC Linear Scales ST46-EZA

- NC Linear Scales ABS ST700

- NC Linear Scales ABS ST1300

- NC Linear Scales AT211

- NC Linear Scales ABS AT1100

- NC Linear Scales ABS AT1300

- NC Linear Scales AT402E

- NC Linear Scales AT203

- NC Linear Scales AT402E with cable A/B

- NC Linear Scales AT402E with cable C

-

Opbouwlinialen

- Terug Opbouwlinialen Opbouwlinialen

- Horizontal ABSOLUTE Scale Coolant Proof IP66

- Horizontal ABSOLUTE Scale Standard

- Horizontal ABSOLUTE Scale Measurement Direction Switching

- Horizontal ABSOLUTE Scale Diameter Function

- Vertical ABSOLUTE Scale Standard

- Vertical ABSOLUTE Scale Measurement Direction Switching

- Vertical ABSOLUTE Scale Diameter Function

-

Data Management

- Terug Data Management Alle Data Management

-

Data Management Software

- Terug Data Management Software Data Management Software

- MeasurLink 10

- USB-ITPAK

-

Mini Processors

- Terug Mini Processors Mini Processors

- Digimatic Mini Processor DP-1VA LOGGER

- Signaal kabels

- Draadloze communicatie

- Interfaces

-

Timerbox, Digimatic Switch Box, Tolerance Box

- Terug Timerbox, Digimatic Switch Box, Tolerance Box Timerbox, Digimatic Switch Box, Tolerance Box

- Digimatic Timerbox

- Digimatic Switch Box

- Industries

- Smart Factory

- Service

-

Educatie

- Terug Educatie

- Educatie

- Education Pack

- E-Learning

- Online Material

-

Over ons

- Terug Over ons

- Over ons

- Ontdek Mitutoyo

-

Certificeringen en legitimiteit

- Terug Certificeringen en legitimiteit

- Certificeringen en legitimiteit

- Certificaten & Accreditaties

- Legitimiteit van de producten (FAKE)

- Mitutoyo Danmark

- Merchandise

-

Nieuws

- Terug Nieuws

- Nieuws

-

Onze promoties

- Terug Onze promoties

- Onze promoties

- Pers informatie

- Evenementen

-

Alle nieuwsberichten

- Terug Alle nieuwsberichten

- Alle nieuwsberichten

- Klantcase - Mitutoyo en Nemera: Partnerschap op het gebied van nauwkeurige farmaceutische apparatuur

- EMO 2025

- Klantcase - Ceratec en Mitutoyo profiteren van elkaars expertises

- TechDemoweek 2025

- MITUTOYO VERSTERKT MET R&D DE EIGEN MARKTGEDREVEN AANPAK

- MITUTOYO, CRAFT EDUCATION EN DMG MORI BRENGEN METEN EN MAKEN BIJ ELKAAR

- Downloads

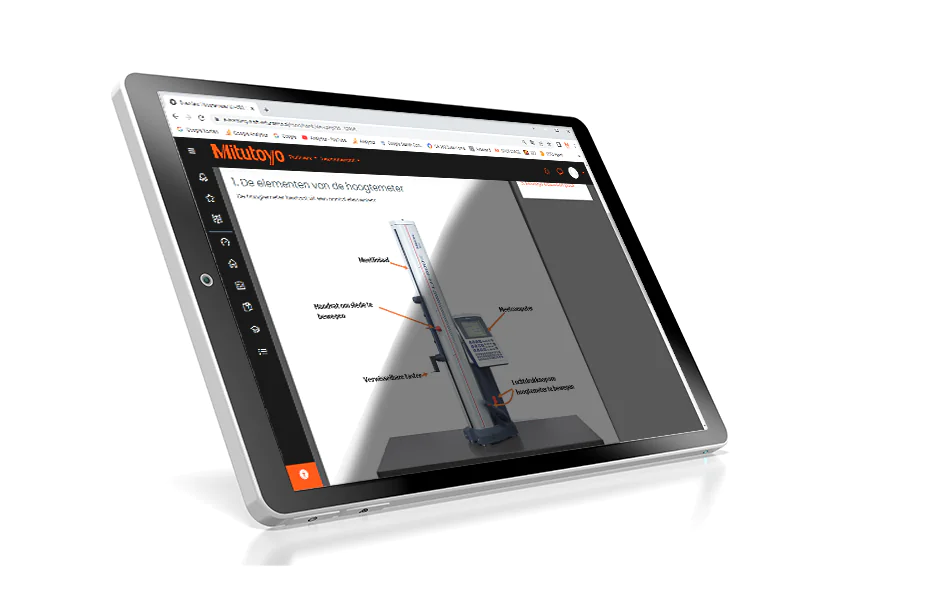

> E-Learning Course

Measuring Basics & Handheld Tools

During the course of this online program, handheld measuring tools are extensively discussed. What the dos and don'ts of each measurement tool are, as well as, the theory of the measuring device itself, and even the field of application of measuring devices are discussed.

Course Details

>Introduction to Measuring

>Small Measuring Instruments: Functions and Area of Application

>Calipers

>Micrometers

>3-point Bore Micrometers

>Depth Micrometers

>Gauge Blocks

>Indicators and Dial Test Indicators

>Height Gauges

>Tasks for Small Measuring Instruments

>Surface Roughness

>Additional Practical Tasks

>Measuring in Practice

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities

- Technical engineers and operators

- Service and sales specialists/consultants technical goods

- Interested individuals with basic technical knowledge

Course Duration: 10 - 15 hours

> E-Learning Course

Linear Height - 2D Measurement System

Learning how to properly use a linear height is a very impressive skill in the quality control world, and in this program, we focus on Mitutoyo's widely used LH-600. In this online course, you will learn, among other things, the correct execution of measurements, reading in and calling up the probe, serial measurements, and reading out the measurement data.

Course Details

>Overview

- Height gauge properties

- Main features

>Switching On and Initial Settings

- Switching on

- Absolute zero point

- Incremental zero point

- Measurement chain values

>Measure and Call Up Probe

- Measure probe diameter

- Save probe

- Call button

- Depth probe

>1D Measurements

- Top surface measurement

- Bottom surface measurement

- Thickness measurement (external)

- Inner size measurement

- Determine the highest point

- Hole measurement

- Shaft measurement

- Determine the vertical distance

- Flat scanning

- Measure squareness

>Tolerances

- Add tolerance to measurement

>Serial Measurements

- Create program

- Repeat program

>Other

- Delete measured values

- Settings

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities

- Technical engineers and operators

- Service and sales specialists/consultants technical goods

- Interested individuals with basic technical knowledge

Course Duration: 4 - 5 hours

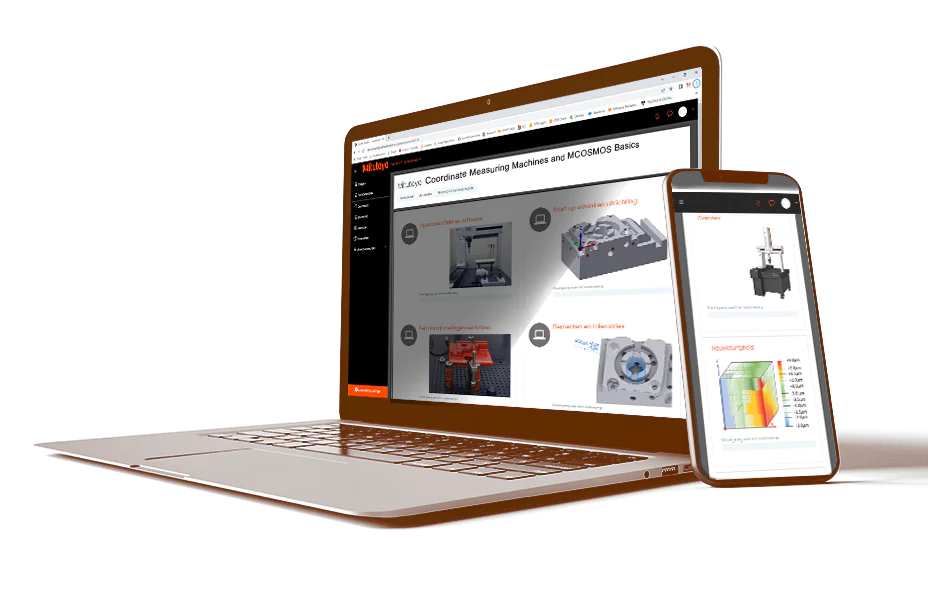

> E-Learning Course

Coordinate Measuring Machines (CMMs) and CMM Data Processing Software Basics (MCOSMOS)

In this course, you will take a closer look at the technology of a CMM which will enable you to work with Mitutoyo's well-known data processing software MCOSMOS (Version 5).

Learn all about a CMM's construction, accuracy, measurement techniques, probing systems, fixturing methods, and all tips and tricks required to efficiently and safely operate a high-end 3-dimensional measuring machine.

The MCOSMOS training covers the basics of the software, setting up test jobs at lightning speed, manually measuring individual elements and evaluating them, handling large amounts of data, and making it available across all the networked areas of the production chain. To truly get an understanding of what makes a CMM tick, this course is right for you!

Course Details

>Starting Up the CMM and the Software

>Start-Up Wizard and Set-Up

>Taking Measurements

>Elements and Tolerances

>Position Tolerances, Measurement Report, and Angular Rotations

>Start-Up of an Existing Measurement Program

>Overview CMM

>Accuracy

>Probing Systems

>Probe Shaft Materials and Choices

>Fixturing

>Software and Their Main Features

>Measuring Technics

>Maintenance

>Reference Guide

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities (advanced knowledge required)

- Skilled technical engineers/metalworkers and CMM operators

Course Duration: 14 - 18 hours

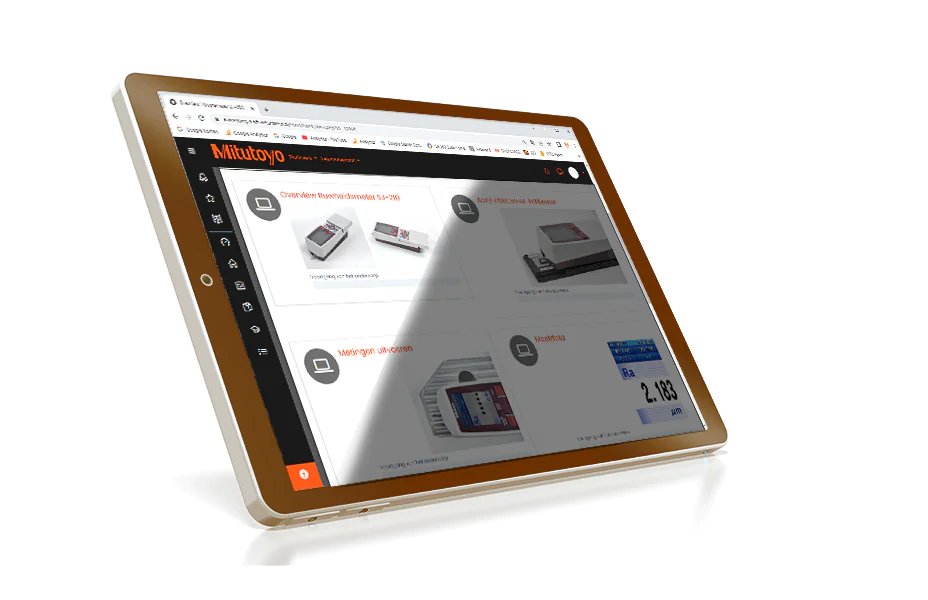

> E-Learning Course

Portable Surface Roughness Testers

Surface roughness measurement can be tricky, learn how easy it is to do this with Mitutoyo's portable surface roughness tester the Surftest SJ-210. This course will help you to master all your surface roughness measuring tasks - from the theory of surface roughness, measuring basics, how to choose the correct standards, picking good profiles and parameters, filtering, and many other beneficial topics.

Course Details

>Overview The Roughness Tester SJ-210

>Switching On/Off and Calibration

>Performing Measurements

>Measuring Data

>Measuring via PC

>Accessories

>Settings

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities

- Technical engineers and operators

- Service and sales specialists/consultants technical goods

- Interested individuals with basic knowledge of a theory of surface roughness

Course Duration: 4 - 6 hours

> E-Learning Course

Data Collection and Real-Time Statistical Process Control with

MeasurLink 9

Get all of the information you need to master data collection and data analysis, monitoring, measurement system analysis, gauge inventory, calibration control, and much more with Mitutoyo's newest generation of our top-of-the-line data collection and SPC software.

In this course, we cover the basics of the MeasurLink modules: Support Center, Real-time Inspection Wizard, Process Analyzer, Report Scheduler, and Security Center.

Learn to add measuring tools and stations, set up a measuring scheme and monitor them in real-time, build dashboards, and discover how to interpret measured values, create reports, or analyze the data in the Process Analyzer.

Course Details

>Overview of the Modules

>Working With a Measuring Tool in MeasurLink

>Making a 2nd Run

>Adding an Image to a Run

>Traceability and Report

>Real-Time Data and Interval Measurement

>Proces Analyzer

>Security Center

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities

- Technical engineers and operators

- Service and sales specialists/consultants technical goods

- Interested individuals with basic technical knowledge

Course Duration: 10 - 12 hours

> E-Learning Course

Geometrical Deviations and Tolerances

This course is teaching you all basics and detailed scientific backgrounds for engineering tolerances and relationships including symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describe nominal geometry and its allowable variation.

It will enable you to understand the various geometric tolerances (e.g. form, orientation, location, run-out) and how to interpret them on an engineering drawing for manufacturing, measure and define a particular form, orientation, location, or run-out tolerance.

Course Details

>What is Geometrical Tolerancing

>Indications

>Datum Reference and Datum Targets

>Form Tolerances

>Orientation Tolerances

>Location Tolerances

>Run-Out Tolerances

>Additional Symbols and Characters

>Geometric Tolerancing in PMI

>Practice Assignments

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities

- Technical engineers and operators

- Interested individuals with basic technical knowledge

Course Duration: 8 - 10 hours

> E-Learning Course

Reading Technical Drawings

Engineering drawings are more than simply a drawing, each one is a rich and specific outline that shows all the information and requirements needed to manufacture an item or product. This course teaches you that engineering drawings offer a lot more specific information and requirements than what a 2D or 3D-Model can do. Learn about Information, Title and Revision blocks, Bill of Material, Lines, and Tolerances. In addition, this course also covers the very basics of geometric tolerances, a much-needed skill in the world of quality control.

Course Details

>Reading a Technical Drawing in a Nutshell

>Views

>Line Types

>Dimensioning

>Dimensional Tolerancing

>Section Views

>Scales

>Geometrical Tolerancing

>Surface Roughness Symbols

>Welding Indications

>Flat Patterns

Target Group and Course Duration

Targeted Audience:

- Students in technical vocational schools and universities

- Technical engineers and operators

- Service and sales specialists/consultants technical goods

- Interested individuals with basic technical knowledge

Course Duration: 24 - 30 hours